Et spiralem-type mixer dewatering apparatus non solum altus-concentration derelinquere sed etiam incumbo et dewater humilis-concentration purgamentum. Et applicabiles caeno concentration potest pervenire (V) mg / l-(L) mg / l.

Celeritas est 2-4 revolutiones per minute, et average industria consummatio est 1/8 de illo de balteus TRADUCTOR et 1/20 de illius centrifuge. Et unitas potentia consummatio est solum 0.01-.1KWH / KG-DS.

Quisque paro of apparatu siccitatibus corporis pulsus per independens variabilis frequency motor, quod incipit aequaliter et singulis paro potest coepi vel obturat independenter.

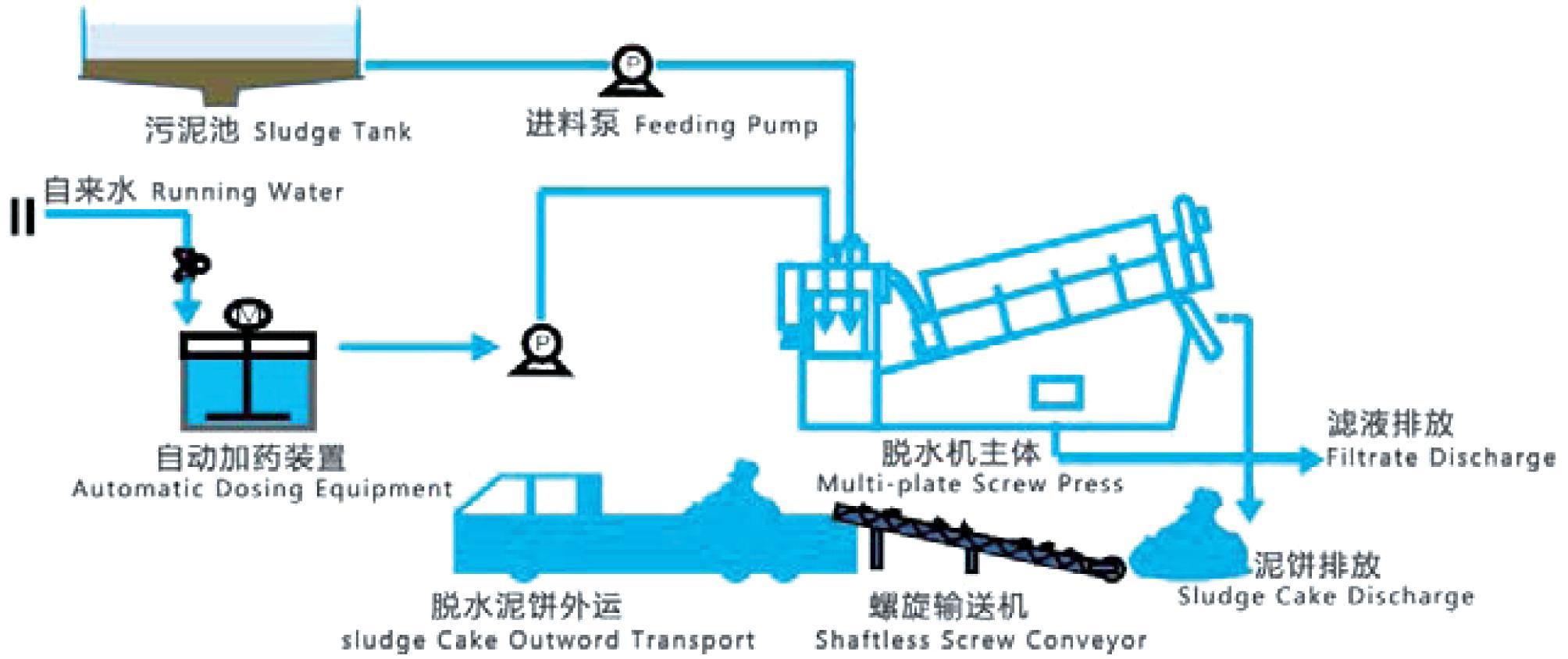

The spiral stacking sludge dewatering machine occupies a small area and can directly process the sludge in the aeration tank and the secondary sedimentation tank without setting up a sludge concentration tank, saving investment in supporting equipment such as mixers, air compressors, and flushing pumps.

| Exemplar | DS Sludge curatio facultatem | Sludge fluxus ageretur facultatem | ||||

| 10000mg / l | 20000mg / l | 30000mg / l | 40000mg / l | 50000mg / l | ||

| Qbdl131 | VIII ~ 14kg / h | ~ 1M³ / h | ~ 0.5M³ / h | ~ 0.4M³ / h | ~ 0.3M³ / h | ~ 0.28M³ / h |

| Qbidil201 | XV ~ 20kg / h | ~ 1.5M³ / h | ~ 0.75M³ / h | ~ 0.6M³ / h | ~ 0.5M³ / h | ~ 0.4M³ / h |

| Qbdl202 | XXX ~ 40kg / h | ~ 3m³ / h | ~ 1.5M³ / h | ~ 1.2M³ / h | ~ 1M³ / h | ~ 0.8M³ / h |

| Qbdil251 | XLV ~ 60kg / h | ~ 2m³ / h | ~ 1M³ / h | ~ 0.9M³ / h | ~ 0.85M³ / h | ~ 0.8M³ / h |

| Qbdl252 | XL ~ 80kg / h | ~ 4M³ / h | ~ 2m³ / h | ~ 1.8M³ / h | ~ 1.7M³ / h | ~ 1.6M³ / h |

| Qbdil301 | XXXV ~ 70KG / h | ~ 5m³ / h | ~ 2.5M³ / h | ~ 2m³ / h | ~ 1.5M³ / h | ~ 1.4M³ / h |

| Qbdl302 | LXX ~ 140KG / h | ~ 10M³ / h | ~ 5m³ / h | ~ 4M³ / h | ~ 3m³ / h | ~ 2.8M³ / h |

| Qbdil303 | 105-210kg / h | ~ 15M³ / h | ~ 7.5M³ / h | ~ 6M³ / h | ~ 4.5M³ / h | ~ 4.2M³ / h |

| Qbdl304 | CXL ~ 280kg / h | ~ 20m³ / h | ~ 10M³ / h | ~ 8M³ / h | ~ 6M³ / h | ~ 5.6M³ / h |

| Qbdil351 | LXX ~ 120kg / h | ~ 10M³ / h | ~ 5m³ / h | ~ 4M³ / h | ~ 3m³ / h | ~ 2.4M³ / h |

| Qbdl352 | CXL ~ 240kg / h | ~ 20m³ / h | ~ 10M³ / h | ~ 8M³ / h | ~ 6M³ / h | ~ 4.8M³ / h |

| Qbdil353 | CCX ~ 360kg / h | ~ 30M³ / h | ~ 15M³ / h | ~ 12M³ / h | ~ 9M³ / h | ~ 7.2M³ / h |

| Qbdl354 | CCLXXX ~ 480KG / h | ~ 40M³ / h | ~ 20m³ / h | ~ 16M³ / h | ~ 12M³ / h | ~ 9.6M³ / h |

| Qbdil401 | C ~ 160kg / h | ~ 13M³ / h | ~ 6.5M³ / h | ~ 5m³ / h | ~ 4M³ / h | ~ 3.2M³ / h |

| Qbdl402 | CC ~ 320kg / h | ~ 26M³ / h | ~ 13M³ / h | ~ 10M³ / h | ~ 8M³ / h | ~ 6.4M³ / h |

| Qbdil403 | CCC ~ 480kg / h | ~ 39M³ / h | ~ 19.5M³ / h | ~ 15M³ / h | ~ 12M³ / h | ~ 9.6M³ / h |

| Qbdl404 | CD ~ 640kg / h | ~ 52m³ / h | ~ 26M³ / h | ~ 20m³ / h | ~ 16M³ / h | ~ 12.8M³ / h |

| Exemplar | Motricium Power (KW) | Baptismum aquam pressura | Baptismum Aquarum (L / h) | Sustentationem Frequentia | PARTIS postea exolvuntur (Year) | |||

| Crispum Shaft | Mixer | Summa | Crispum Shaft | Movable Orbis | ||||

| Qbdl131 | 0.18 | 0.18 | 0.36 | 0,1mipa- 0.2impa (Sine pressura Flushing Equipment) | 28 | 5min / h | 5 | 3 |

| Qbdl201 | 0.37 | 0.18 | 0.55 | 32 | 5 | 3 | ||

| Qbdl202 | 0.74 | 0.55 | 1.29 | 64 | 5 | 3 | ||

| Qbdl251 | 0.55 | 0.37 | 0.92 | 40 | 5 | 3 | ||

| Qbdl252 | 1.1 | 0.55 | 1.65 | 80 | 5 | 3 | ||

| Qbidil301 | 0.75 | 0.55 | 1.3 | 40 | 10 | 5 | ||

| Qbdl302 | 1.5 | 0.75 | 2.25 | 80 | 10 | 5 | ||

| Qbdl303 | 2.25 | 1.1 | 3.35 | 120 | 10 | 5 | ||

| Qbdl304 | 3 | 1.1 | 4.1 | 160 | 10 | 5 | ||

| Qbidil351 | 1.1 | 0.75 | 1.85 | 60 | 10 | 5 | ||

| Qbdl352 | 2.2 | 1.1 | 3.3 | 120 | 10 | 5 | ||

| Qbdil353 | 3.3 | 1.5 | 4.8 | 180 | 10 | 5 | ||

| Qbdl354 | 4.4 | 1.5 | 5.9 | 240 | 10 | 5 | ||

| Qbdil401 | 1.5 | 1.1 | 2.6 | 80 | 10 | 5 | ||

| Qbdl402 | 3 | 1.5 | 4.5 | 160 | 10 | 5 | ||

| Qbidil403 | 4.5 | 1.1 1.1 | 6.7 | 240 | 10 | 5 | ||

| Qbdl404 | 6 | 1.1 1.1 | 8.2 | 320 | 10 | 5 | ||

| Exemplar | Screw specs | Sludge MUSTA missionem altitudo (mm) | Altiore dimensionem (mm) | Pondus retia | Operating pondus | ||

| Longitudo (L) | Width (w) | Altitudo (h) | |||||

| Qbdl131 | × × × ф130 | 240 | 2000 | 790 | 1040 | 250 | 395 |

| Qbdl201 | × × I | 350 | 2550 | 900 | 1300 | 420 | 540 |

| Qbdl202 | ф × II | 350 | 2600 | 1050 | 1300 | 550 | 660 |

| Qbdl251 | × I ф | 380 | 2750 | 950 | 1450 | 550 | 680 |

| Qbdl252 | ф × II ф | 380 | 2800 | 1150 | 1450 | 650 | 800 |

| Qbdl301 | × I ф300 | 530 | 3380 | 980 | 1760 | 900 | 1300 |

| Qbdl302 | × × II ф300 | 530 | 3580 | 1320 | 1760 | 1350 | 2000 |

| Qbdl303 | фз00 × з | 530 | 3730 | 1590 | 1760 | 1900 | 2700 |

| Qbdl304 | фз00 × IV | 530 | 3830 | 1985 | 1750 | 2500 | 3600 |

| Qbdl351 | × × I ф350 | 570 | 4160 | 1100 | 2250 | 1100 | 2000 |

| Qbdl352 | × × × ф350 | 570 | 4380 | 1495 | 2250 | 2100 | 3250 |

| Qbdl353 | фз50 × з | 570 | 4580 | 1955 | 2250 | 3100 | 4600 |

| Qbdl354 | фз50 × IV | 520 | 4230 | 2370 | 2040 | 4100 | 5700 |

| Qbdl401 | × × I ф400 | 660 | 4520 | 1250 | 2150 | 2200 | 4200 |

| Qbdl402 | × × II ф400 | 660 | 4770 | 1685 | 2150 | 3500 | 6000 |

| Qbdl403 | з з з ф | 660 | 4800 | 2520 | 2150 | 5500 | 8000 |

| Qbdl404 | ф × IV | 660 | 5000 | 3150 | 2150 | 7000 | 9500 |

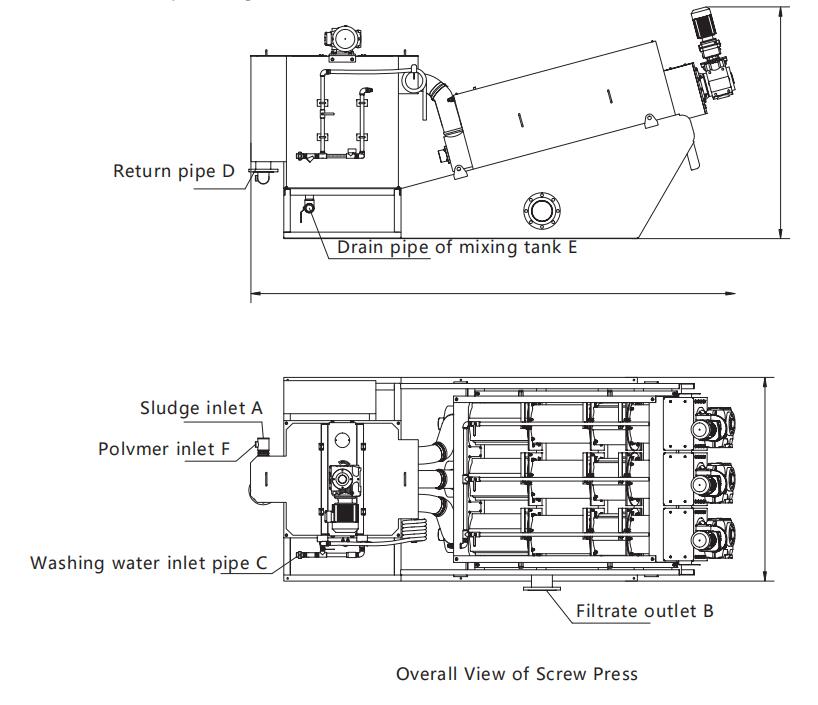

| Exemplar | Aquarum exitus c | Refluxus ostium D | E Missionis Portus de Mixing Tank E | Dosing Portus F | Filtrate Outlet G |

| Qbdl131 | DN20 | Dn65 | Dn40 | DN20 | Dn65 |

| Qbdl201 | DN20 | Dn65 | Dn40 | DN20 | Dn80 |

| Qbdl202 | DN20 | Dn65 | Dn40 | DN20 | Dn80 |

| Qbdl251 | DN20 | Dn65 | DN40 | DN25 | Dn80 |

| Qbdl252 | DN20 | Dn65 | Dn50 | DN20 | DN150 |

| Qbdl301 | DN20 | DN150 | Dn65 | DN25 | Dn125 |

| Qbdl302 | DN20 | DN150 | Dn65 | DN25 | Dn125 |

| Qbdl303 | DN20 | DN150 | Dn65 | DN25 | Dn125 |

| Qbdl304 | DN20 | DN150 | Dn65 | Dn32 | DN150 |

| Qbdl351 | DN20 | DN150 | Dn65 | DN25 | Dn125 |

| Qbdl352 | DN20 | DN150 | Dn65 | DN25 | Dn125 |

| Qbdl353 | DN20 | DN150 | Dn65 | Dn32 | DN150 |

| Qbdl354 | DN20 | DN150 | Dn65 | DN32 | DN150 |

| Qbdl401 | DN20 | DN150 | Dn65 | DN25 | Dn125 |

| Qbdl402 | DN20 | DN150 | Dn65 | DN32 | DN150 |

| Qbdl403 | DN20 | DN150 | Dn65 | Dn50 | Dn200 |

| Qbdl404 | DN25 | DN150 | Dn65 | Dn50 | DN200 |

Just dices salve et youll 'satus a fructuosum collaboration. Satus vestri propria elit.

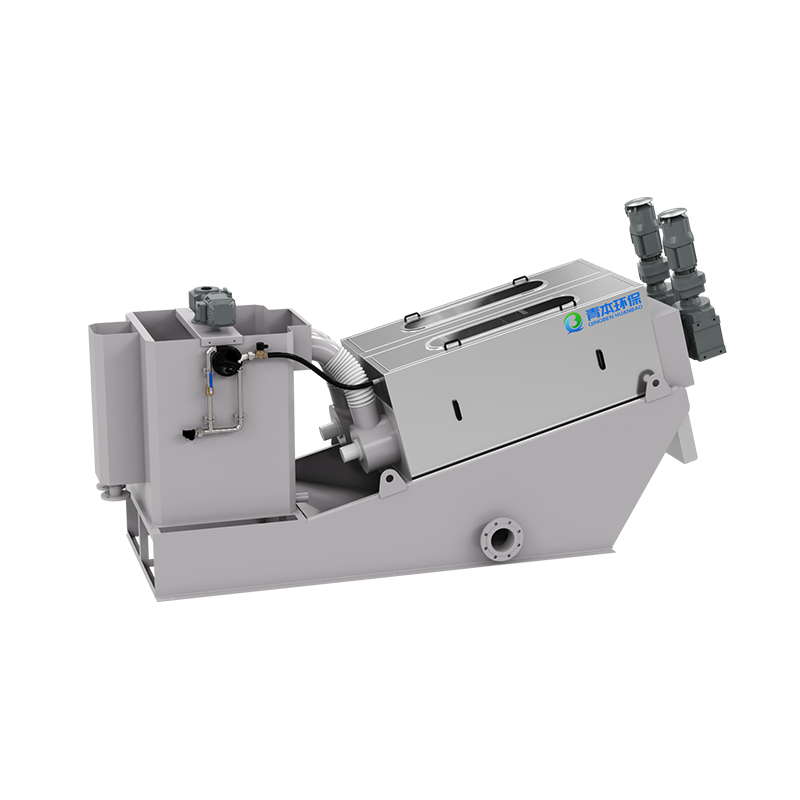

Ut in agro in agro innovative curatio, in spiralis laminated sidge dewatering apparatus Quae facti sunt indispensable industriae curatio apparatu in environmental praesidium industria cum suis unique consilium conceptum et efficiente. Qingben Environmental Donec Technology (Jiangsu) Co., Ltd Focuses in fabricare de caeno et wastewater curatio apparatu. Hodiernae solidum-liquida separator Quae developed in efficiens siccitatibus ratio integrating mechanica vestibulum, materia scientia et intelligentes imperium technology, et late in industria et emergentes environmental tutela.

Laminated caeno dewatering apparatus integrates automatic control arca, Flocculation Conditioning tristique, caeno concentration et siccitatibus corporis, liquida collectione cisternina. Eam realizes efficiens Floculation sub automated operationem, continuously complet caeno concentration, expressis et siccitatibus, et tandem redit vel obit et collected filtrate. In solidum-liquida separator separat solidum et liquidum in mixta liquidum a corporalis vel mechanica modo, et ludit a key munus in resource recuperatio, pollutio et productionem efficientiam emendationem. Hodie, spiram laminated caeno dewatering apparatus est derived a diversitas technica route, tegere amplis scenarios de traditional vestibulum ut emergentes environmental tutela industrias.

In futurum, solidum-liquida separators et develop in directionem modulaization et integration. Mobile siccitatibus unitates potest cito applicantur ad subitis curatio missionibus, ut purgamentos curatio post clades. Rotatione spiralis harundo agitet in natantis circulum ad Rotate continue. In apparatu innititur motus inter fixum anulum et natantis anulum ad consequi continua siccitatibus, callide avoiding communi bicket forsit de traditional dehydrators. Stricter Aliquam Protection ordinationes Promovere technological innovation, sed altus-concentration et humilis-fluxus purgamentorum curatio et particula separationis accurate lenimentus sunt adhuc in focus in technicae breakthroughs, quod requirere interdisciplinary Research Support ut materiae et fluidum Mechanicis.

Ut magna technica carrier ad industriae constructione, spiralis laminated sidge dehydrator est omnino mutata in caeno curatio processus. Cum deepening de "Dual ipsum" belli, hoc technology cum tam mechanica praecisione et environmental amicitia erit permanere dimittere innovative vitale in global environmental praesidium industria.